| Minimum Order Quantity | 5 Unit |

| Usage/Application | Industrial, Commercial |

| Driven Type | Electric |

| Sealing Type | 3/4 Side Seal center seal |

| Roll Width | 90mm, 150mm |

| Machine Motor | 1/2 HP |

| Electrical Supply | 220 V AC, Single Phase, 50 Hz |

| Machine Weight | 350 Kg approx |

| Power Consumption | 2 kW approx |

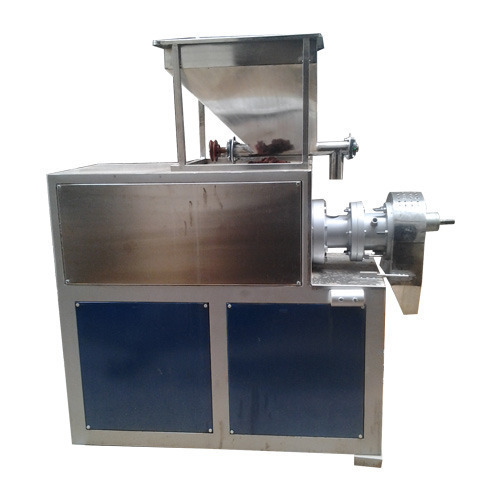

Owing to our vast experience in the concerned industry, we are offering a comprehensive array of Dip Tea Bag Packing Machine.

- Efficient, effective packing

- The machine is centrally controlled, Has a digital display

- Easy to Operate/Less Servicing

- Required

- No rusting

- Ease of installation and shifting

- To print M.R.P, Month of packing, Lot No. Etc.

- Displays/controls Sealing Temperature of Sealers

- Product Application: Powder, Granules

- Sealing Type: 3/4 Side Seal center seal

- Machine Motor: ½ HP, Single Phase, 50 Hz

- Feeding System: Volumetric Cup Filler

- Packing Film: Any heat sealable laminated roll

- Machine Control Through: PLC (Programmable Logic Control)

- Photocell Registration System: Yes

- Contact Part: Stainless Steel

- Heater Load: 100 W x 2 Nos.; 200 W x 2 Nos

- Packing Film Pulling: Through electromagnetic clutch and brake

- Temperature Controller: PID Based

- Machine Speed (approx): 30-50 Pouches per Min (With Paper) (Depends upon quantity and product)

- Machine Motion: Intermittent

- Optional Features (At an extra cost): Batch Coding Device Nitrogen Flushing System Batch Cutting